The equipment selection phase is a critical component of any construction project. It involves the process of identifying and evaluating the various equipment and machinery required to complete the project. This phase is crucial as it can have a significant impact on the project’s success, cost, and timeline. The selection of the right equipment can lead to increased efficiency, productivity, and profitability, while the wrong choice can result in delays, budget overruns, and reduced quality. In this guide, we will explore the key considerations and steps involved in the equipment selection process to help you navigate this critical phase successfully.

Understanding the Equipment Selection Phase

Importance of Equipment Selection

Equipment selection is a critical aspect of any project that can have a significant impact on its outcomes. The right equipment can help ensure the success of a project, while the wrong equipment can lead to delays, increased costs, and reduced efficiency. Here are some key reasons why equipment selection is so important:

- Affects project outcomes: The equipment you choose can significantly impact the quality and quantity of work that can be completed. For example, selecting the wrong type of equipment can lead to delays in completing a project, which can have a ripple effect on the entire project timeline. On the other hand, selecting the right equipment can help ensure that work is completed efficiently and effectively, leading to better project outcomes.

- Impacts cost and timeline: Equipment selection can also have a significant impact on project costs and timelines. Selecting the wrong equipment can lead to increased costs due to repairs, maintenance, and downtime. Conversely, selecting the right equipment can help reduce costs by improving efficiency and reducing the need for repairs and maintenance. Similarly, the wrong equipment can lead to delays, while the right equipment can help keep projects on schedule.

- Affects overall efficiency: Equipment selection can also impact overall project efficiency. The right equipment can help streamline processes, reduce bottlenecks, and improve productivity. Conversely, the wrong equipment can lead to inefficiencies, such as increased downtime, reduced productivity, and decreased morale. By selecting the right equipment, you can help ensure that your project runs smoothly and efficiently, leading to better outcomes and higher levels of satisfaction.

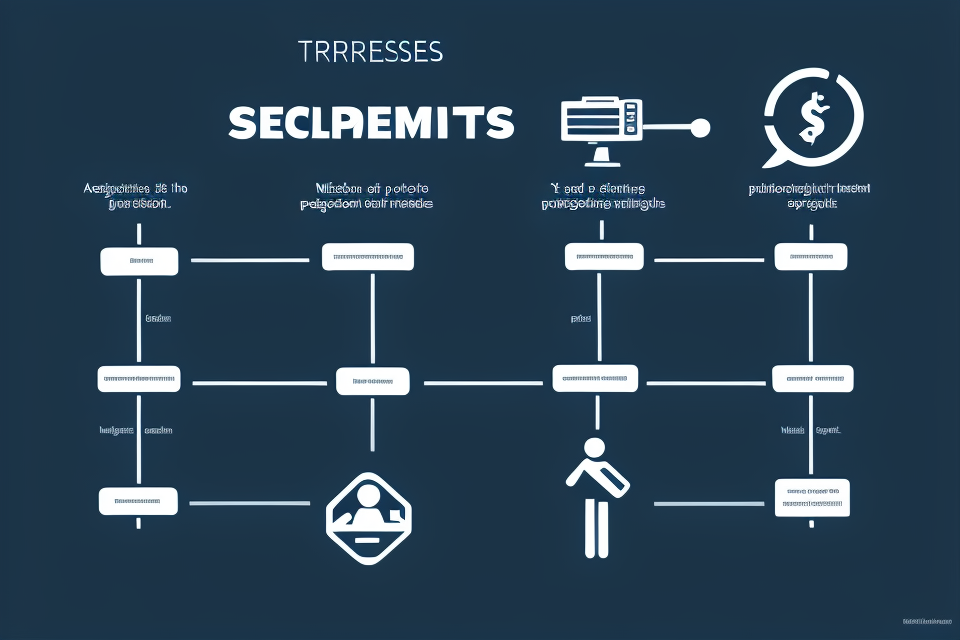

Factors to Consider

Equipment selection is a critical process that requires careful consideration of various factors. It is important to select the right equipment to ensure the success of a project and the efficiency of operations. The following are some of the factors that should be considered during the equipment selection process:

- Project Requirements: The first factor to consider is the project requirements. The equipment selected should be able to meet the specific needs of the project. This includes factors such as the scope of the project, the timeline, and the budget. For example, if the project requires the use of heavy machinery, the equipment selected should be able to handle the weight and size of the materials being used.

- Budget Constraints: Budget constraints are another important factor to consider during the equipment selection process. The equipment selected should be within the budget allocated for the project. It is important to consider the total cost of ownership, including the initial purchase price, maintenance costs, and operational expenses.

- Operational Needs: The operational needs of the project should also be considered. This includes factors such as the location of the project, the climate, and the accessibility of the equipment. For example, if the project is located in a remote area, the equipment selected should be able to withstand harsh weather conditions and be easy to maintain.

- Maintenance Considerations: Maintenance considerations are also important when selecting equipment. The equipment selected should be easy to maintain and repair. This includes factors such as the availability of replacement parts, the skill level required to perform maintenance, and the cost of maintenance.

- Technological Advancements: Finally, technological advancements should also be considered during the equipment selection process. The equipment selected should be able to integrate with other technologies and be able to handle new software and applications. This includes factors such as the compatibility of the equipment with other systems, the ability to upgrade the equipment, and the ability to integrate with new technologies.

By considering these factors, you can ensure that you select the right equipment for your project, within your budget, and that meets the operational needs of your project.

The Equipment Selection Process

Step 1: Identify Project Requirements

Determine Project Goals and Objectives

The first step in the equipment selection process is to determine the project goals and objectives. This involves understanding the overall purpose of the project and what outcomes are expected. For example, if the project is to build a new manufacturing facility, the goal may be to increase production efficiency and reduce costs. The objectives could include specific targets for output, cost savings, and quality control. It is important to clearly define the goals and objectives of the project, as they will serve as a foundation for the rest of the equipment selection process.

Assess Operational and Performance Requirements

Once the project goals and objectives have been established, the next step is to assess the operational and performance requirements of the equipment. This involves identifying the specific tasks that the equipment will be required to perform, as well as any performance metrics that must be met. For example, if the project is to build a new manufacturing facility, the equipment will need to be able to handle specific production volumes, meet quality standards, and operate within certain temperature and humidity ranges. It is important to carefully assess the operational and performance requirements of the equipment, as they will dictate the type and specifications of the equipment that is selected.

Evaluate Site-Specific Conditions

The final step in identifying project requirements is to evaluate site-specific conditions. This involves considering factors such as the physical layout of the site, any environmental factors, and any local regulations or codes that must be adhered to. For example, if the project is to build a new manufacturing facility in a remote location, the equipment will need to be able to operate in extreme temperatures and be able to withstand harsh weather conditions. It is important to carefully evaluate site-specific conditions, as they can have a significant impact on the type and specifications of the equipment that is selected.

Overall, the first step in the equipment selection process is to identify the project requirements. This involves determining the project goals and objectives, assessing the operational and performance requirements, and evaluating site-specific conditions. By carefully considering these factors, it is possible to select the right equipment for the project, ensuring that it meets the specific needs and requirements of the project.

Step 2: Conduct Research

Gather Information on Available Equipment

- Utilize online resources such as manufacturer websites, industry publications, and equipment directories

- Attend trade shows and demonstrations to see equipment in action

- Consult with industry experts and peers for recommendations

Compare Features, Specifications, and Capabilities

- Create a checklist of must-have features and prioritize them

- Evaluate equipment based on performance, efficiency, and durability

- Consider the compatibility of equipment with existing systems and processes

Consider Manufacturer Reputation and Support

- Research the manufacturer’s history and reputation in the industry

- Evaluate the availability and quality of customer support and service

- Consider the manufacturer’s commitment to innovation and sustainability

By conducting thorough research, you can make an informed decision when selecting equipment that meets your needs and budget.

Step 3: Develop Equipment List

Creating a list of potential equipment options is a crucial step in the equipment selection process. It is essential to evaluate each option against the project requirements to ensure that the equipment meets the necessary specifications. Here are some steps to follow when developing an equipment list:

Identify the Equipment Needs

The first step in developing an equipment list is to identify the equipment needs of the project. This involves determining the type and quantity of equipment required to complete the project successfully. It is essential to consider the specific functions that the equipment will perform and the project’s timeline.

Research Equipment Options

Once the equipment needs have been identified, the next step is to research equipment options that meet those needs. This can involve looking at manufacturer websites, industry publications, and talking to equipment suppliers. It is important to gather as much information as possible about each piece of equipment, including its specifications, features, and cost.

Evaluate Equipment Options

After researching equipment options, it is essential to evaluate each option against the project requirements. This involves comparing the equipment’s specifications and features to the project’s specifications and requirements. It is also important to consider the cost of each piece of equipment and how it fits into the project’s budget.

Narrow Down the List

Based on the initial assessment, it is time to narrow down the list of potential equipment options. This involves selecting the equipment that best meets the project requirements and fits within the project’s budget. It is important to document the reasons for selecting each piece of equipment to ensure that the decision-making process is transparent and can be justified.

In summary, developing an equipment list involves identifying equipment needs, researching equipment options, evaluating each option against project requirements, and narrowing down the list based on the initial assessment. By following these steps, you can ensure that you select the right equipment for your project, which will help you achieve your project goals efficiently and effectively.

Step 4: Request Proposals and Quotes

- Reach out to equipment suppliers and manufacturers: The next step in the equipment selection process is to reach out to equipment suppliers and manufacturers. This step involves identifying potential suppliers that can provide the equipment you need, and then contacting them to request proposals and quotes.

- Obtain detailed proposals and quotes: Once you have identified potential suppliers, the next step is to obtain detailed proposals and quotes from them. A proposal is a detailed document that outlines the equipment specifications, pricing, and terms and conditions of the sale. A quote, on the other hand, is a formal offer from the supplier to provide the equipment at a specific price.

- Evaluate proposals based on equipment specifications, pricing, and terms: After obtaining proposals and quotes from different suppliers, the next step is to evaluate them based on equipment specifications, pricing, and terms. It is important to carefully review the proposals and quotes to ensure that they meet your needs and budget. You should also consider the reputation of the supplier and their ability to deliver the equipment on time.

Overall, the equipment selection process involves several steps, including identifying your needs, researching equipment options, developing a shortlist of potential equipment, evaluating proposals and quotes, and finally, making a decision. By following these steps, you can ensure that you select the right equipment for your needs and budget.

Step 5: Conduct Site Visits and Demonstrations

- Arrange site visits and equipment demonstrations

- Reach out to equipment manufacturers and dealers to schedule visits to their facilities or to arrange for equipment demonstrations at your own site.

- This will give you the opportunity to see the equipment in action and get a better understanding of its capabilities and limitations.

- Observe equipment in action

- During the site visits and demonstrations, take note of how the equipment performs in different scenarios and operating conditions.

- Observe how easily the equipment can be operated and maintained, and whether it requires specialized training or equipment.

- Assess operational and maintenance requirements

- Determine whether the equipment meets your operational requirements and can be integrated into your existing systems and processes.

- Evaluate the maintenance requirements of the equipment, including the availability of spare parts and the need for specialized maintenance equipment.

- Consider the costs associated with maintenance and repairs, and whether they are within your budget.

Step 6: Finalize Equipment Selection

At this stage, you will have evaluated several options, and it’s time to make a final decision. To finalize equipment selection, follow these steps:

- Compare all options based on project requirements, cost, and performance: Consider the key factors that you identified earlier in the process, such as project requirements, budget, and performance. Compare the selected equipment options against these criteria to determine which option best meets your needs.

- Make an informed decision: Based on your analysis, select the equipment that best meets your project requirements, is within your budget, and provides the desired performance. Make sure to document the reasoning behind your decision for future reference.

- Document the decision-making process for future reference: It’s essential to document the decision-making process for future projects. This documentation can help streamline the selection process in the future and provide a reference for making similar decisions. Keep the documentation organized and easily accessible for future reference.

Remember, finalizing equipment selection is a critical step in the process, and it’s essential to make an informed decision based on your analysis and project requirements. Documenting the decision-making process can help you in the future and ensure that you have a well-organized and accessible record of your decision-making process.

Tips for Successful Equipment Selection

When it comes to selecting equipment for a project, there are several important tips to keep in mind to ensure a successful outcome.

Establish Clear Project Goals and Objectives

Before you begin the equipment selection process, it’s essential to establish clear project goals and objectives. This will help guide your decision-making process and ensure that you select equipment that aligns with your project’s needs. Be specific about what you want to achieve and what the equipment should be capable of doing.

Involve Stakeholders in the Decision-Making Process

Involving stakeholders in the decision-making process is critical to ensure that everyone’s needs are considered and that there is buy-in from all parties involved. This can include project managers, engineers, maintenance personnel, and other key stakeholders. Consider setting up a selection committee to help with the decision-making process and ensure that everyone’s voice is heard.

Consider Long-Term Costs and Benefits

When selecting equipment, it’s important to consider not just the upfront costs, but also the long-term costs and benefits. This can include factors such as operating costs, maintenance costs, and the potential for future upgrades or replacements. Be sure to consider the total cost of ownership over the life of the equipment.

Prioritize Safety and Reliability

Safety and reliability should be top priorities when selecting equipment. Be sure to consider factors such as the equipment’s safety features, reliability, and any potential hazards or risks associated with its use. Don’t compromise on safety or reliability, as these are critical factors that can impact the success of your project.

Evaluate Equipment Suppliers and Manufacturers

When selecting equipment, it’s important to evaluate suppliers and manufacturers to ensure that you’re getting high-quality equipment from a reputable source. Consider factors such as the supplier’s reputation, the quality of their products, and their level of customer support. Don’t be afraid to ask for references or to reach out to other customers to learn more about their experiences with the supplier or manufacturer.

Plan for Maintenance and Support

Finally, it’s important to plan for maintenance and support throughout the life of the equipment. Consider factors such as the availability of spare parts, the cost of maintenance, and the level of support offered by the supplier or manufacturer. Having a plan in place for maintenance and support can help ensure that your equipment remains in good working order and that any issues are addressed quickly and efficiently.

FAQs

1. What is the equipment selection phase?

The equipment selection phase is the process of identifying and evaluating the necessary equipment and tools required for a construction project. This phase involves researching and comparing different types of equipment, assessing their features and capabilities, and determining which equipment will best meet the project’s requirements and budget.

2. Why is the equipment selection phase important?

The equipment selection phase is critical because it can significantly impact the success and efficiency of a construction project. Selecting the right equipment can improve productivity, reduce costs, and ensure that the project is completed on time and within budget. On the other hand, selecting the wrong equipment can lead to delays, increased costs, and reduced quality.

3. What factors should be considered during the equipment selection phase?

During the equipment selection phase, several factors should be considered, including the project’s scope, size, and location. Other factors to consider include the type of work to be performed, the equipment’s capabilities and limitations, the cost of the equipment, and the availability of the equipment. It is also essential to consider the equipment’s maintenance and repair requirements, as well as the skills and experience of the equipment operators.

4. How do you evaluate the cost of equipment?

When evaluating the cost of equipment, it is essential to consider both the purchase price and the operating costs. The purchase price includes the initial cost of the equipment, while the operating costs include expenses such as maintenance, repairs, fuel, and labor. It is also essential to consider the residual value of the equipment, which is the value of the equipment at the end of its useful life.

5. How do you determine the appropriate equipment for a project?

To determine the appropriate equipment for a project, it is essential to assess the project’s requirements and constraints. This includes evaluating the project’s size, scope, and location, as well as the type of work to be performed. It is also essential to consider the skills and experience of the equipment operators and the availability of the equipment. Once the necessary equipment has been identified, it is essential to compare different types of equipment and assess their features and capabilities to determine which equipment will best meet the project’s requirements and budget.